The world of motion control transformed by a single invention.

HarmonicDrive® inventor C. W. Musser

HarmonicDrive® inventor C. W. Musser

The unique principle of the HarmonicDrive® was based on a brand new concept. The mechanism was the brainchild of the American inventor Clarence Walton Musser. Musser was a brilliant inventor who was awarded more than 1,500 patents, in a wide range of fields going even beyond his specialty in mechanical engineering to include also physics, chemistry, and biology.

Prior to his invention, efforts to achieve greater speed and accuracy in gear mechanisms for conveying driving power and motion were focused solely on making the gear mechanism more rigid. The principle of the HarmonicDrive® by contrast was to make use of the flexibility of metal and apply elastic dynamics. Since this method of conveying motive power turned conventional wisdom on its head, it suddenly became the object of worldwide interest. Two companies then stepped forward to bet on the chances of commercializing this concept. One was the U.S. company United Shoe Machinery Corporation (USM) and the other was Hasegawa Gear Works, Ltd., the forerunner of Harmonic Drive Systems Inc.

Life of C. W. Musser

| 1909 |

Born in Lancaster, Pennsylvania |

| 1921 |

Father Ezra died when Clarence was just 12 years old |

| 1926 |

Graduated from Manheim Township High School |

| 1937 |

Married Edna June 23 |

| 1943 |

Completed the world's first recoilless rifle |

| 1947 |

Completed the initial model of a personal catapult for emergency ejection from high-speed aircraft, for the U.S. Air Force |

| 1955 |

Applied for a basic patent (in the U.S.) for strain wave gearing |

| 1958 |

Applied for spline and rotary table patents (in the U.S.; strain wave gearing application with revised gear engagement theory; same patents applied for in Japan in 1963) |

| 1960 |

Announced the new field of "elastic-body mechanics" at the 6th conference of the American Society of Mechanical Engineers |

| 1964 |

NASA adopted a strain wave gearing mechanismwhose trade name is "RESPONSYN" in the solar panel winches on its Skylab weather satellite |

| 1965 |

Gave a lecture on the HarmonicDrive® theory to three engineers of Hasegawa Gear Works, Ltd. at USM Co., Ltd. based on a technical support agreement between the two companies |

| 1968 |

Won a mechanical design award from the American Society of Mechanical Engineers (ASME) |

| 1998 |

Died on June 8 |

Having served as certified engineer in the states of Pennsylvania and Massachusetts, Musser polished his skills at many universities including M.I.T. and the University of Pennsylvania, then went on to become a professional inventor, forming consultancy contracts with the U.S. Government and a number of companies such as General Motors, Olin Mathieson, and United Shoe Machinery.

During World War II, Musser's efforts paid off in the invention of the recoilless rifle. This invention was awarded 61 patents, and Musser personally oversaw its manufacture and prototype testing. Around the same period Musser developed many safety devices for aircraft including a cartridge-driven catapult, canopy jettison system, and parachute release device.

HarmonicDrive® inventor C. W. Musser

HarmonicDrive® inventor C. W. Musser

After the war, Musser went on to become the pioneer in the new HarmonicDrive® field of mechanics actively introducing elastic deformation. For this mechanism he was awarded more than 70 patents in 15 countries.

Among his other accomplishments are plastic products and elaborate testing and measuring equipment. His patents in the U.S. number more than 200, and many more of his patents have been announced in at least 28 countries.

Musser's life work is best expressed in the way he himself described his philosophy:

"It is never a question as to whether it can be done — it is only whether one cares to spend the time and effort."

— C. W. Musser

Musser Heritage Room

A Musser Heritage Room was opened in October 2006 on the Hotaka Plant site (Azumino-shi, Nagano Prefecture) with exhibits relating to C. W. Musser.

The items on display include machine tools and measurement instruments actually used by Musser, his papers, patent materials and prototypes around the time he invented the harmonic drive, and other objects, which were presented to HDSI thanks to the kindness of his surviving family.

The entranceway arch, the wooden furniture in the hall, and the fixtures adopt a design modeled after his home laboratory.

Inside the Musser Heritage Room

Inside the Musser Heritage Room

Entrance of the Musser Heritage Room modeled after his home laboratory

Entrance of the Musser Heritage Room modeled after his home laboratory

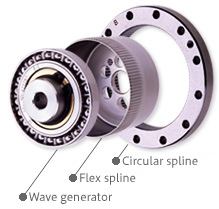

The HarmonicDrive® applying the elastic dynamics of metal

The HarmonicDrive®, applying the elastic dynamics of metal, consists of just three basic components: a wave generator, flex spline, and circular spline.

Wave generator

The wave generator has small ball bearings embedded in the outer circumference of the elliptical cam. The inside raceway is fixed to the cam, while the outer raceway is subjected to elastic deformation through the ball bearings. The wave generator is ordinarily attached to the input shaft.

Flex spline

The flex spline is shaped like a shallow cup, with very thin sides. Teeth are positioned radially around the outside of the cup opening. The bottom of the flex spline (cup bottom) is called the diaphragm and is ordinarily attached to the output shaft.

Circular spline

The circular spline is a rigid circular ring. Teeth are positioned on the inside of the ring, and are two more in number than those on the flex spline. It is normally fixed to a casing.

When Musser invented "strain wave gearing," it was called "HarmonicDrive®," which was the name used when it was patented. Later Harmonic Drive Systems Inc. succeeded in making practical application of the technology in Japan.

Note that the academic and generic name of such a device is "strain wave gearing." HarmonicDrive® is a registered trademark that can be used only with products manufactured and sold by the HDS Group.